Tea Machinery Manufacturers

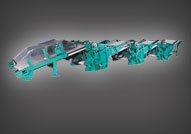

Continuous Oxidisation Machine

Download eBrochure

A unique designed continuous fermenting machine - having an individual Stainless Steel Hopper connected with S.S. Tapered duct for the humid air provided from the mist chamber.

Zenifer - PVD fermentation is comparable with the level of floor fermentation.

The Wonder Mesh (PES) has got certain unique advantages:

- This mesh has got 46% open area which is about 85% - 87% more in comparison to SS-Belt and Trays which ensures uniform oxidisation.

- The wonder mesh is available upto 8' wide enables wider machines shorter in length to accomodate in the space constrained factories.

- To control the movement of Wonder Mesh, Rubberised Conveyor Rollers, specially designed Idler and S.S. Plates are provided.

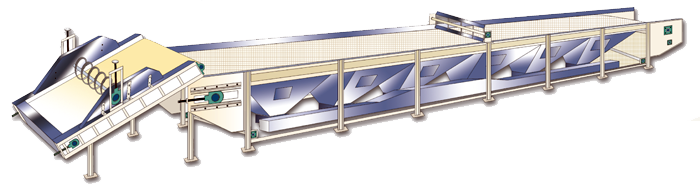

Full Width Feed Conveyor

Suitable Full Width PVC Feed Conveyor with synchronised speed arrangement and spiral spreader is provided to Uniform Controlled feeding of Dhool Mal (Ensuring Better Quality of Tea)

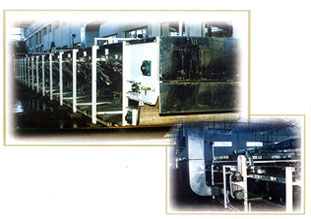

Controlled Humidity & Temperature

For the supply of fresh humid air suitable Humidification arrangement is incorporated with the machine. This ensures adequate Hygrometeic difference & supply of air for better Oxidation.

Air Distribution

S.S. aerodynamically designed plenum chamber with suitable airduct & individual dampers facilitates continuous uniform distribution of humidified air throughout the effective area of the machine to ensure consistently producing good quality tea.

Upturner

For Belts and even fermentation through out the Bed a slow speed S.S. Upturner is provided. It is specially designed to make sure the grades are not disturbed.

Design

Neat as well as sturdy. The tea bed is uniformly and evenly maintained. Low height ensures better inspection & supervision. No accumulation or spillage of tea. This machine is ideal for on line manufacturing process.

Optional Features

- Pneumatic Auto Belt Tracking System: The System ensures self aligment of the run of the mesh belt hance avoids damages.

- Discharge Conveyors: Collection conveyors at the discharge end of the machine either of twin type or standard type can be provided.

- Ball Separator cum Ball Breaker: This is very innovative system. Unlike the other, here only Ball Mal goes to the ball breaker. Therefore 90% - 95% mal is not subjected to breaking and additional handling. Very vital for upkeeping the qualities. This can be used under the googie or at the discharge of fermenting machine.

Centralised Control Console with AC variable speed drive (Optional)

Composite Centralised Console is provided for easy control & operation. An AC variable speed regulator is optional. The Regulator ensures the exact fermenting time and avoids the tedious job of changing the pilleys or shifting the V-Belts.

| Dimensions | 5m (mm) | 6m (mm) | 7m (mm) | 8m (mm) | |||

| Overall Length W/O feed Conveyor | 11505 | 13410 | 15315 | 17220 | |||

| Overall Length with Feed Conveyor | 13791 | 15696 | 17601 | 19506 | |||

| Overall Width (with G.B. Table) | 2845 | 2845 | 2845 | 2845 | |||

| Overall Height | 1280 | 1280 | 1280 | 1280 | |||

| Effective Tea Bed Length (without Feed) | 10515 | 12420 | 14325 | 16230 | |||

| Effective Fermenting Width | 1830 | 1830 | 1830 | 1830 | |||

| Feeding Height of Feed Conveyor | 940 | 940 | 940 | 940 | |||

| Discharge Height from Floor Level | 430 | 430 | 430 | 430 | |||

| Tea Bed Height from Floor level | 1080 | 1080 | 1080 | 1080 | |||

| Fermenting Time range | 30 mins to 150 mins | ||||||

| Capacity (withered leaf) kg** | 910 | 1080 | 1260 | 1440 | |||

** At 4" thickness, 50 min fermenting time & leaf conditions

| Power Requirement | 5m (mm) | 6m (mm) | 7m (mm) | 8m (mm) | ||

| Main Motor | 2 HP | 3 HP | 3 HP | 3 HP | ||

| Upturner | 1 HP | 1 HP | 1 HP | 1 HP | ||

| Feed Conveyor | 1 HP | 2 HP | 2 HP | 2 HP | ||

| Cleaner | 1 HP | 1 HP | 1 HP | 1 HP | ||

| Discharge (Optional) | 1 HP | 1 HP | 1 HP | 1 HP | ||

| Humidifiers Fan | 5 HP | 5 HP | 5 HP | 5 HP | ||

| Humidifiers | 1 HP | 1 HP | 1 HP | 1 HP | ||

| Cleaning System | 2 HP | 2 HP | 2 HP | 2 HP | ||

NOTE: Due to continuous process of development the design is subject to change without notice.