Tea Machinery Manufacturers

Sorting Machines

Download eBrochure

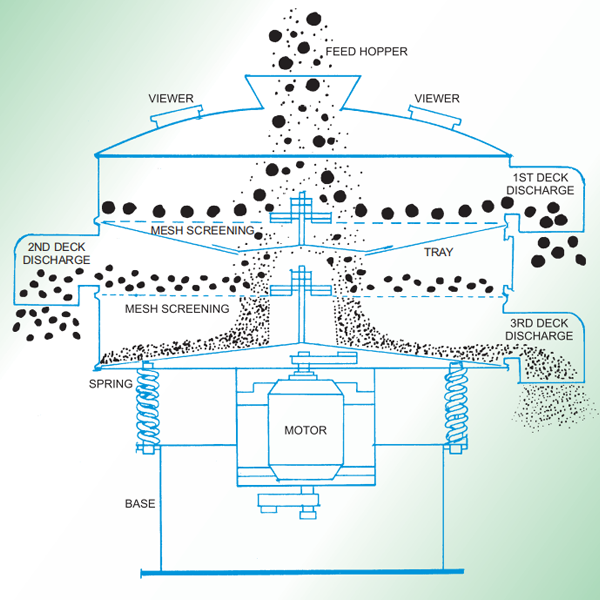

Sectional View & Working Principle

Space, Speed, Compactness and versatility are the prime factors of 'Zenith' Vibro Screen to replace the old conventional sorting machineries with a view of economy and efficiency. This has revolutionised the sorting system. The 'Zenith' Vibro Screen, a self balancing machine, in M.S. Construction has a modular arrangement. This consists of upto 7 Decks and each Deck is provided with S.S. (AISI-304) Screens of different meshes, as per the Nos. of mesh required. The whole assembly resting on several heavy duty springs are securedly fixed to a heavy M.S. Circular base.The vibrating assembly is isolated by a cone mounted spring assembly. The drive consists of 1.5 HP (1.1 kw) totally enclosed heavy duty specially designed Vibrating Motor and is housed inside the chamber. The different weights at different angles are eccentrically attached on both ends of the Motor shaft. By changing the position of both the eccentric weights, the efficiency of the screening changes. The gyratory motion of the motor vibrates the upper deck freely and no vibration the ground floor.

Dimension and Technical Details

| Inside of the machine | 48" | ||

| Height (Overall Height) | 7 Decks | 1490 mm | |

| 5 Decks | 1265 mm | ||

| Circumference | - | 50" | |

| No. of Decks-Normally preferred | - | 3/7 Decks. | |

| Each Deck width | - | 112mm | |

| Steel Base Height. | 390 mm | ||

| Output per hour | 700kgs |

Electric Motor

HP (1.1 kw) specially designed vibrating motor totally enclosed, heavy duty suitable for operation 400/400 V, 3 Phase, 50 Cycles A.C. Power.

Advantages & Benefits

- The sorting and grading of Teas are perfect on this machine and no re-processing is required.

- It requires less floor space and keeps floor clean.

- It upkeeps the appearence and the bloom of the Tea because of the minimum handling.

- It is 100% leak - proof and spillage free.

- It consumes less HP and requires minimum labour with higher output and thereby minimum cost of sorting.

- Minimum maintenance cost.

- Interchangeability of Decks and screening meshes.

- No concrete foundation is required.

- Conveyorisation is simple and easy.

- Almost no sound - it is just Humming.

- Cleaning of all parts is simple and easy.

- With spare screens of various mesh sizes,quick changeover is possible to meet various grade requirements.

- Nos. of Decks can be provided as per requirements i.e. 3,5 & 7 Decks.

- Being very simple in design and of high technology standards with rigid constitution,no after sales service is required.

- Just on - the -switch and get the clean graded teas continuously.