Tea Machinery Manufacturers

Converisation Automation

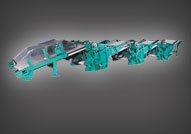

Zenith designs and undertakes total conveyorisation of Tea factory including automation of turn key-basis conveyorisation for online processing & sorting is inevitable and has the following advantages

- Enables Reduction power in the factory.

- Enables to keep factory floor neat & clean.

- Avoids mis-handling of Tea which reflects upon the quality

- Improves productivity of the machines.

- Enhances hygienic values in the factory and of the produce.

For checking the trueness and matching of the rollers :

Inspection Bench - is necessary.

For grinding the used but usable Milling Cutters and Chasers, when the same have blunted.

Cutter & Chaser Grinder - is necessary.

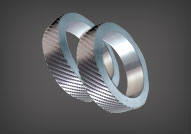

Roller Sharpening Machines.

The Bed and pedestal are made of specially graded close grained Cast Ironand are sturdy heavy in construction with wider bed capable of absorbing any shock and vibration. The gears and hardened ground with precision finished. They are simple in operation and user friendly. A centralised control panel with indicator lamps is also provided for effecient operation and monitering.

'Zenith' Special purpose CTC Roller Chasing Lathe Machine

This Machine is used for circumferential grooving on the segmental roller. An attachment for holding the chaser (2.1/4" or 1") is provided with additional sliding and centering facility for setting the chaser correctly for pitch matching.

CTC Rollers upto 48"long and dia upto 14" can be filled and grooved. The Machine is provided with oil; filled all geared head stock with alloy steel spindle, Heavy duty bearing for troublefree smooth Heavy duty 4 Jaw independent chuck, special lead screw with centricast phospher Bronze nut for backlast free movement of chaser , microdial graduated in 0.001".

The machine is having forwarded & reversed drives and gear box drive directly coupled to motor.

Zenith Special Purpose CTC Roller Milling Machine

This machine is used for Helical grooving on the segmental rollers. Indexing device is fitted on the diving head with mechanical cuttertilt arrangement to enable easy and accurate adjustment of the cutter gear box.

CTC roller upto 48" long and dia upto 14" can be fitted and grooved. The machine is provided with microdial gradduated in0.001" to control depth of cut, six heavy duty bearings for regid support, mechanical steady drive.

Normally lead of milling groove is fixed at 24". But to adjust helix angle as per the diameter of the roller, cutter tilt arrangement for setting correct required helix angle and tooth ratio, is provided.

The machine is supplied complete with A.C. Electric motor and starter, limit switch, pipes and fittings, necessary tools, tray and Safety guards. Special arrangements for Continuous flow of coolant while grooving, is provided with collant storage tank.

"ZENITH" Special Purpose CTC Roller Milling-Cum-Grooving Lathe Machine

This machine is used for dual operations of aircumferential grooves as well as helical grooves. Once circumferential grooves are completed, then helical grooves are done . That means one by one operation.

In this machine oals CTC rollers upto 48" long and dia upto 14" can be grooved on both the operations.

The machine is provided with indexing device fitted on the dividing head, chaser holder, mechanical cuttertilt arrangement, microdial graduated in 0.001", Hardened and grounded with precision finishing worm spindle, centrifugally cast phospher bronze worm wheels, Heavy duty Rollers steady with six roller bearing for rigid support, Rack and pinion for easy positioning of dteady.

The machine is supplied complete with electric motor, change over starter, push button starter, limit switches, pipes and fittings, tools, trays, coolant arrangement and safety guards.

Note: Individual Milling Machine and individual grooving lathe is preferably against combined machine for better accuracy & highet output.

Tool & Cutter Grinder

This machine is used for sharpening of blunt tools i.e. Cutters & chaser for their re-use to their maximum life.

The grinding attachments are fitted on the strong M.S. fabricated C.I. base. The milling cutter is mounted on a spindle which rotates on roller bearings.

The combined table unit fitted with cross slide, saddle and table unit is swivellable and travers through a rack & pinion for easy movement. The cross feed movement is graduated in 0.001" division for fine grading and swivel base LH and RH cutters accurately to correct angles. Limit stops are provided to prevent fouling of the grinding wheel. The chaser fixture can accommodate either 2¼" wide or 1" wide chaser which is provided with diamond dresser for dressing the grinding wheel. The chaser should be passed briskly across the wheel to aviod overheating.

This is complete with all fixtures & fittings and electrical.

This can be used for sharpening other general purpose tools as well.