Tea Machinery Manufacturers

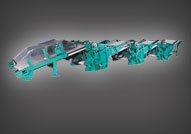

Continuous Fermenting Machine

The process of oxidation is called Fermentation. Although fermentation process starts the moment Tea Leaves are ruptured. But normally fermentation process is considered after having tea leaves processed i.e. Crush, Tear & Curl. The process is not only important but very critical and vital as well and is directly responsible for quality of tea. Activation of enzymes, chemical reactions and changes in colour and smell- all this happen in this process. Temperature, humidity, air changes and hygienic conditions are determining factors for good quality. Existing systems of fermentation being practised are viz- Floor fermentation, Gumlah fermentation and Monorail tray fermentation. The continuous fermenting machine is the latest technology and can be termed as moving floor with controlled conditioning.

Zenifer is the latest development of the continuous Fermenting machine. Designed to over-come all the problems of fermentation process to deliver the best. It is simple, easy to operate and control and maintain ideal hygienic conditions. This requires less space and labour and is hassel-free. Once this is set to motion, you relax and get the Best fermented dhool mal.

Zenifer continuous Fermentor from zenith offers all these features and much more.

Salient Features

- High Output : High through put upto 1400 kgs. Withered leaf per hour can be achieved depending on the size of the machine, spread thickness, and fermenting time.

- Low Height : The machine is only 4'6" high from the ground level, easy to supervise, clean & maintain.

- Trays : Heavy duty and rugged, perforated stainless steel trays allow the humidified air penetration through the leaf for proper and even fermentation.

- Drives : A sturdy variable speed drive facilitates wide variation in fermenting time from 40 Minutes to 160 Minutes.

- Controlled Feed : A suitable feed conveyor with synchronised speed arrangement is provided for uniform controlled feeding, which automatically enhances the performance of the machine.

- Air Distribution : An aerodynamically designed plannum chamber with suitable airduct facilitates uniform distribution of humidified air throughout the effective area of the machine to ensure uniform distribution of air and thereby even and perfect fermentation.

- Humidification Shell : A suitable designed Humidification shell made from GI sheets is supplied as an integral part of this machine which helps in maintaining the required Hygromatic difference which is very crucial & important.

- Centrifugal Fan : A dynamically balanced centrifugal blower suitably designed to supply the humidified air from the shell to the air duct through an overhead or on-ground ducting system, is provided to maintain controlled and desired conditionings.

- Hygiene : A self cleaning easily removable brush to continuously clean the trays is provided. The return circuit of tray and pvc belt is exposed to U/V tubes to extinct the bacterial germination and hazards.

- Flexibility : Suitable for both CTC and Orthodox manufacture.

- Design : Neat as well as sturdy. The Tea bed is uniformly and evenly maintained throughout. All parts are easily accessible for inspection, cleaning and maintenance. No accumulation or spillage of Tea. This machine is ideal for on line manufacturing process.

- Low Maintenance Cost : This machine is virtually maintenance free. Individually trays can be replaced whenever necessary with minimum down time, which is not the case with steel belt fermentators, which require expensive maintenance or replacement with much longer down time.

- Centralised Control Console : A composite centralized console is provided for easier and faster controls and operations.

- Optional - On Request : collection conveyor at discharge end of the machine.

| ZF 48 (6 modules) | ZF 54 (7 modules) | ZF 60 (8 modules) | |

| Length | 15.5 Mt.(51') | 17.4Mt(57') | 19.3Mt(63') |

| Height | 1.4Mt(4'6") | 1.4 Mt(4'6") | 1.4Mt(4'6") |

| Width (including Drive Unit) |

2.8 Mt(9'2") | 2.8Mt(9'2") | 2.8Mt(9'2") |

| Width (including Discharge conveyor) |

4 Mt(13'1") | 4Mt(13'1") | 4Mt(13'1") |

| Width (excluding drive unit & discharge conveyor) | 2.1 Mt (6'11") | 2.1 Mt(6'11") | 2.1 Mt(6'11") |

| Main drive | 5 H.P.(3.7 Kw) | 5 H.P(3.7 Kw) | 5 H.P.(3.7 Kw) |

| Spreader | 1 H.P.(0.75 Kw) | 1 H.P.(0.75 Kw) | 1 H.P. (0.75 Kw) |

| Cleaning Brush | 1 H.P.(0.75 Kw) | 1 H.P.(0.75 Kw) | 1 H.P. (0.75 Kw) |

| Fan | 5 H.P.(3.7 Kw) | 5 H.P.(3.7 Kw) | 7.5 H.P (5.5 Kw) |

| Humidifier | 1 H.P. (0.75 Kw) | 1 H.P. (0.75 Kw) | 1.5 H.P (1.1 Kw) |

| Fermenting capacity (3 1/2" thickness,60min fermenting time & leaf conditions) |

1100 kgs | 1250 kgs | 1400 kgs |